4 Easy Facts About Granite Garage Floors Shown

Wiki Article

The 6-Minute Rule for Concrete Coating

Table of ContentsHow Epoxy Floor can Save You Time, Stress, and Money.The Ultimate Guide To Concrete CoatingNot known Facts About Concrete ResurfaceThe smart Trick of Garage Floor That Nobody is DiscussingA Biased View of Garage FloorSome Of Fort Mill Epoxy

While acrylic finishings can be versatile when integrated with a strong base, they can be prone to damaging when fulfilled with high influence. Its quick-dry time can additionally make it tough to use quickly sufficient without compromising the structure of the material. This can create a total unequal application. Acrylic is most commonly made use of as a clear overcoat, giving you a glossy coating to your concrete surface.Picture credit score: All Garage Floors The last sort of covering is a basic paint finish. While paints are used for numerous things, they can additionally be used for concrete coverings, though not unbelievably popular. Paint is made up mainly of resins, solvents, and also pigment for shade. It is mainly used as a sealer for concrete and is a simple service if you're searching for a fast project.

While paints are not the most long lasting choice for a concrete layer, they can supply an added degree of security over the surface area as an added sealant. Paint can include some defense to concrete, but it is not one of the most durable choice around. Many paints tend to have reduced UV resistance, implying in exterior locations, the color can fade promptly.

Paint finishes are also a great material to use to develop detailed patterns or a work of art as well as are easier to apply in elaborate means than various other coverings. Picture credit score: Bob Vila With many choices available, it can be overwhelming and complex to choose the ideal one for you.

Charlotte Epoxy - An Overview

Polyurea might be the right choice for you. Are you wanting to include a custom-made DIY style to your garage flooring without breaking the bank?You can filter the right concrete coating material types that fit your criteria. At Southwest Exteriors, we provide polyurea finishings from Penntek with a polyaspartic overcoat since of their superior toughness, long life, and general top quality. If you're searching for a one-day, high-grade polyurea concrete layer with personalized style and color alternatives, after that we could be the best service provider for you.

It is very important to understand what all contributes to the overall expense of a concrete layer task so you can have realistic expectations for your job.

The solution calls for complete cookie support in order to watch this web site. Please enable cookies on your web browser and attempt once more. You will be rerouted as soon as the validation is complete.

4 Simple Techniques For Concrete Coating

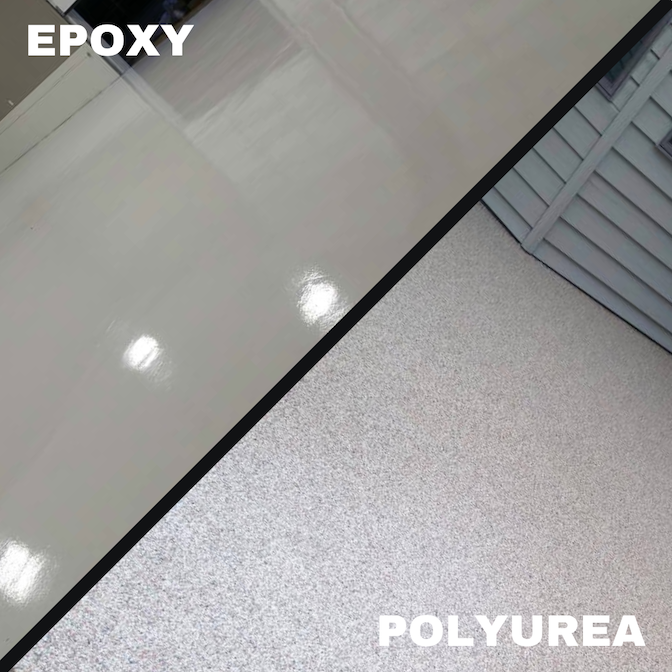

These qualities make epoxy finishes excellent for sturdy applications such as commercial facilities, storage facilities, logistic centers and also various other areas that may be subjected to heavy forklift traffic. Epoxy is also recognized for its resistance to chemical items, such as bleach, oils, oils, cleansers, etc. This chemical resistance makes them a prominent option in garages in the automotive sector.

Polyurethanes are polymers that more helpful hints are attached to a chemical compound team called carbamates. Polyurethane is a thermosetting polymer naturally; i. e., it does not melt when heated. To the untrained eye, polyurethane finishings might show up to be aesthetically comparable to epoxy layered floorings. However, they have unique qualities that make them perfect for details applications. Carolina epoxy.

Some Ideas on Granite Garage Floors You Should Know

This feature makes polyurethane flooring finishings better fit for locations with moderate to hefty pedestrian website traffic (Concrete repair). The boosted elasticity likewise makes polyurethane-coated floors extra resistant to view it abrasion, given that influence lots are quickly taken in and much less prone to create scrapes. The elasticity and also versatility of polyurethane also add to their capability to operate in settings with low freezing temperature levels.One of the various other significant advantages of polyurethane floor layers is their curing time. In contrast, epoxy finishings need at least seven days to cure before they can be all set for usage.

Polyurethane floor coverings are, for that reason, not suggested for usage in locations with high levels of humidity. The appropriate handling as well as application of polyurethane coverings usually need trained and also educated team.

These attributes make epoxy finishings perfect for durable applications such as commercial centers, storage facilities, logistic centers as well as other locations that may be subjected to hefty forklift traffic. To the inexperienced eye, polyurethane finishes may show up to be visually comparable to epoxy covered floors. They have distinctive attributes that make them optimal for specific applications.

This feature makes polyurethane floor layers better suited for areas with moderate to hefty pedestrian traffic. The boosted flexibility likewise makes polyurethane-coated floorings more immune to abrasion, because influence tons are easily soaked up as well as less vulnerable to trigger scrapes. The flexibility as well as adaptability of polyurethane also add to their ability to operate in environments with reduced freezing temperature levels.

One of the other considerable benefits of polyurethane flooring layers is their treating time. Floorings covered with this product can be all find set for operation the next day. In contrast, epoxy finishes require a minimum of seven days to cure before they can be prepared for use. While polyurethane possesses lots of beneficial buildings, they do have a couple of shortcomings.

The Facts About Concrete Resurface Uncovered

Report this wiki page